Air-Cooled Modular Unit

Product Introduction

1. Air-cooled modular unit is highly efficient and energy-saving devices that utilize the thermal energy in the air for heating, cooling and hot water supply. It absorbs low-temperature heat energy from the air, and through the action of the compressor and heat exchanger, transfers the heat energy to the room or water, achieving the regulation of indoor temperature and the supply of hot water.

2. Air -cooled modular unit has the characteristics of environmental protection, energy saving, safety and stability, and is an ideal choice to replace traditional coal-fired and gas-fired equipment.

3. Air-cooled modular unit feature environmental friendliness, energy conservation, safety and stability, making them an ideal choice to replace traditional coal and gas equipment.

Features of Air-Cooled Modular Unit

1. Air-cooled modular units are central air conditioning units that use air as the cold (heat) source and water as the cooling (heat) medium.

The condenser is a finned heat exchanger and the evaporator uses a water-fluorine heat exchanger, such as a shell-and-tube, plate-type heat exchanger.

2. As an integrated unit that serves as both cold and heat source, air-cooled heat pumps eliminate the need for cooling towers, cooling water pumps, boilers and associated piping systems. The system has a simple structure,saves installation space. It's easy to maintenance and management and is energy-saving. It's especially suitable for areas lacking water sources.

3. Air-cooled modular units are usually preferred as an effective supplement in the design of HVAC projects that are cold in winter and hot in summer, have neither heating boilers nor heating networks, or have short and unstable heating periods in the heating networks and require air conditioning throughout the year.

4. The centralized and semi-centralized central air conditioning systems composed of it and terminal devices such as fan coil units and air conditioning boxes have the advantages of flexible layout and diverse control methods.

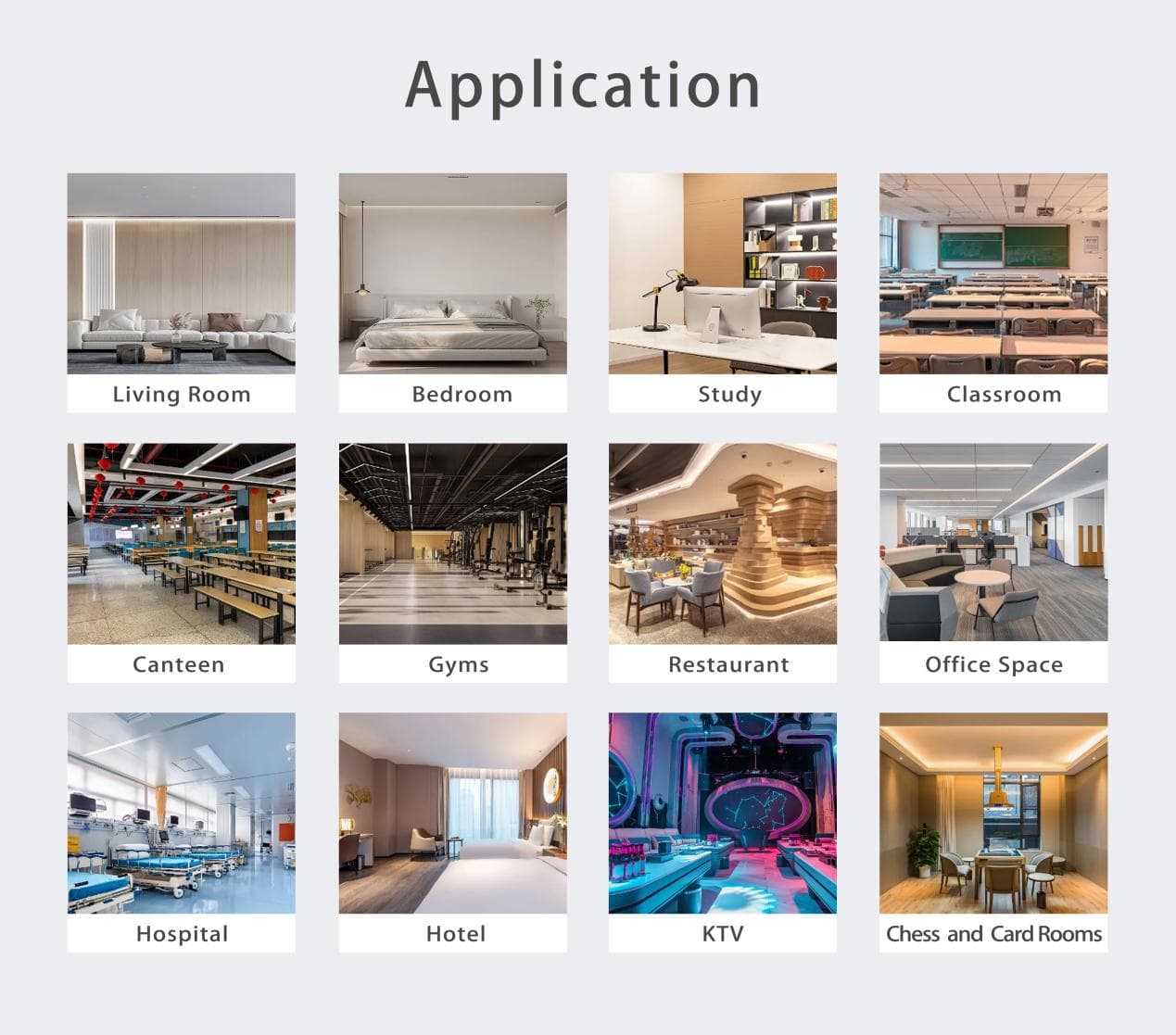

Types of Air Cooled Chiller & Heat Pump

1.Mini Type Air Cooled Scroll Chiller and Heat Pump, 10kW-45kW

The condenser is equipped with high efficiency internally threaded copper pipe and high quality aluminum. The copper tubes are mechanically bonded to aluminum fins, resulting in perfect combination between them. The optimized pipeline flow allows for the best heat transfer effect.

2.Air Cooled Scroll Water Chiller and Heat Pump, 60kW-480kW

Mini type air cooled water chiller and heat pump has the advantages of high efficiency, energy saving, low noise level, reasonable structure, easy operation and maintenance. It is widely used in the central air-conditioning system of construction facilities such as villas, hotels, shopping malls, supermarkets, office buildings, workshops and business clubs.

3.Air Cooled Screw Chiller and Heat Pump, 280kW-1120kW

The air cooled screw chiller and heat pump is used for heating and cooling applications in large commercial structures such as malls, office buildings, workshops, hotels, and hospitals. The air cooling unit is especially preferred in locations in which water is scarce.

Working Principle

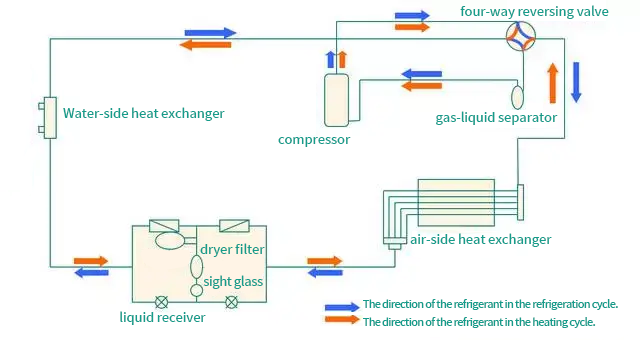

Cooling Mode

Cooling mode: The high-temperature refrigerant gas discharged from the compressor condenses into liquid in the air-side heat exchanger, and after being throttled and depressurized by the throttling device, it enters the water-side heat exchanger, absorbs heat and evaporates before returning to the compressor, completing one refrigeration cycle; at the same time, the air conditioning water from the room is cooled down after passing through the water-side heat exchanger.

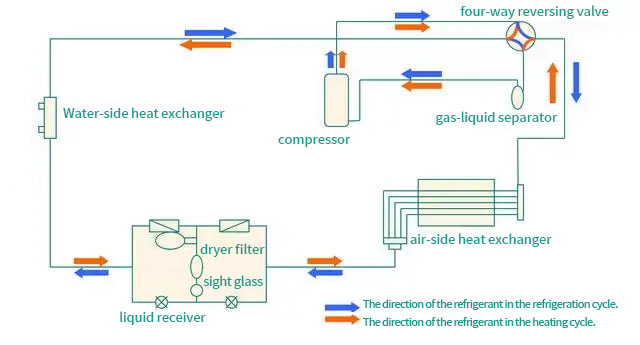

Heating Mode

Heating mode: The high-temperature refrigerant gas discharged from the compressor condenses into liquid in the water-side heat exchanger, and after being throttled and depressurized by the throttling device, it enters the air-side heat exchanger, absorbs heat and evaporates, and then returns to the compressor to complete a heating cycle; at the same time, the air conditioning water from the room is heated after passing through the water-side heat exchanger.

Accessories of Air Cooling Modular Unit

Heat Exchanger

Heat exchanger adopts a fully optimized design, with a reasonable structure, reliable operation, and excellent performance.

It's pressure-resistant and shock-resistant, not easily deformed, allows for unobstructed refrigerant flow, ensures smooth oil return in the pipeline, and has high safety.

Compressor

The compressor is a world-class scroll compressor with low operating noise.

It adopts an optimal intake distribution structure, an asymmetrical scroll plate and a fixed scroll plate with low deformation, which improves the energy efficiency ratio. It also adopts an optimal motor cooling structure, roller bearings and dry bearings to improve reliability and has multiple protection functions, including exhaust temperature protection, high and low pressure protection, over-current protection, and reverse phase protection.

Ventilador

The fan adopts a low-noise axial flow fan, supplemented by a high-efficiency motor to further improve the unit's efficiency and reduce noise.

Thermostatic expansion valve

Imported world-class refrigeration components—thermostatic expansion valves— regulate system flow by adjusting the system's sub-cooling (heating). This unit uses dual thermostatic expansion valves to control flow, with separate control for cooling and heating, resulting in more even capacity adjustment.